Our 3D metrology service

3D digitization

Our 3D metrology service

3D digitization

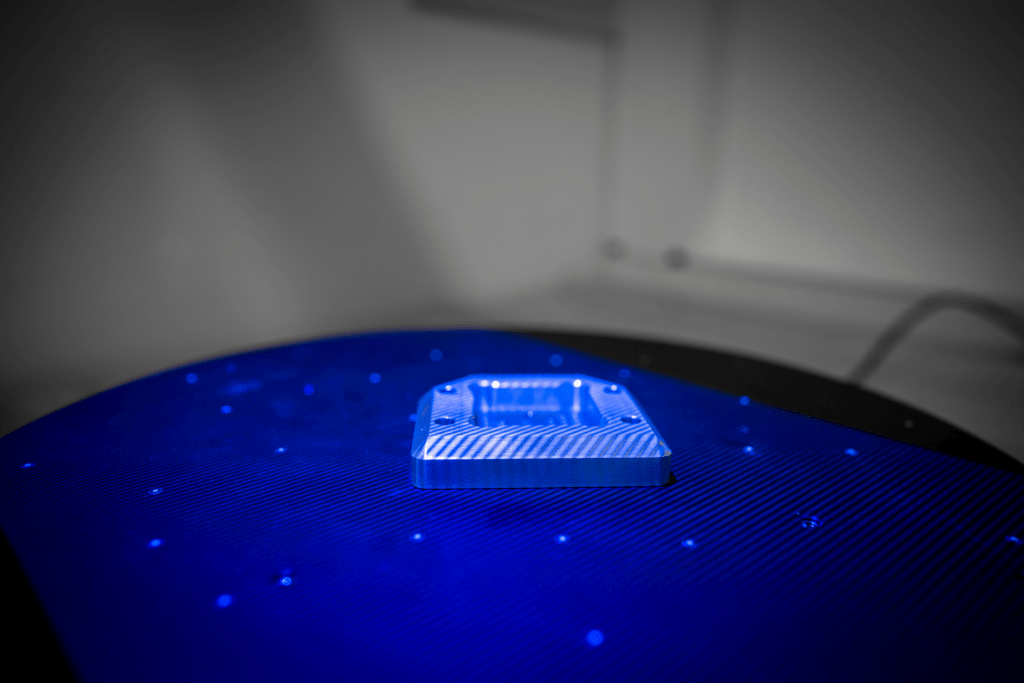

A high-quality form of digitization plays an essential role in optimal object measurement. That is why we work with the precise and flexible 3D scanning systems from GOM. The full-surface measurement data is captured using Blue Light Technology and also enables highly complex components to be scanned. This allows important decisions to be made on product quality.

3D digitization of components

Make your component digitally available: Fast and high-quality measurement using proven triple scan technology.

We measure your component using the precise Blue Light Technology of the GOM brand. The fine stripe pattern of the stereo camera makes it possible to scan your 3D object optimally and deliver measurement data with the highest possible accuracy. This creates an exact 3D surface model of your component, regardless of its complexity. Thanks to digital availability, nothing stands in the way of the engineering and manufacturing process chain!

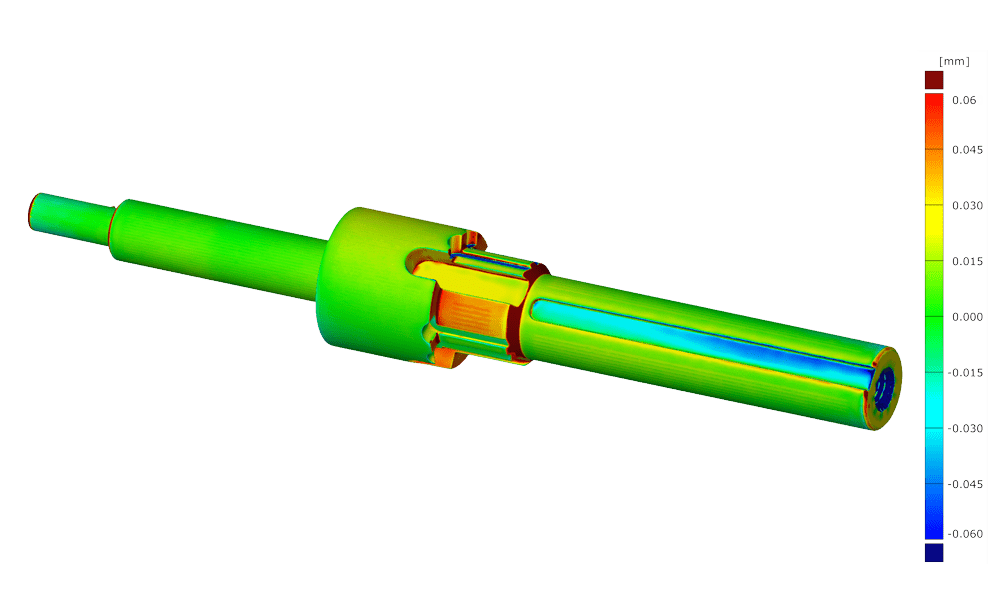

Area comparison / target-actual comparison

A comprehensive deviation display between 3D scan and CAD data.

The planar deviation display between the complete 3D actual coordinates and the CAD data makes it possible to carry out a detailed component evaluation. If adjustments are necessary, this process provides important information for optimizing your prototype. This is made possible by several million points that describe a surface in three dimensions. The result is a precise 3D surface model.

A comparison between the CAD model and the 3D surface model from the scan data subsequently provides a so-called false color image. This high-precision data indicates, among other things, different production factors or possible wear of the individual components. You benefit from our metrology service, especially for prototypes with low production tolerances. In a target-actual comparison, we can respond individually to the improvement of your components.