From the first sketch to …

Engineering

We support your product from the idea to series production. In addition to the creation of prototypes, we are also available for material selection, optimization and functional product testing.

From the first sketch to …

Engineering

We support your product from the idea to series production. In addition to the creation of prototypes, we are also available for material selection, optimization and functional product testing.

Initial consultation | Offer | Full transparency | Project management | Project completion | Ongoing support

We look forward to new challenges! Getting to know you personally is our top priority, so that we can pick you up at the right place with your idea. Once the goals and non-goals of the project have been clearly defined, we package your requirements in a transparent offer. It is important to us that you always find your individual requirements reflected in our implementation recommendation. In this way, we lay the important foundation for successful cooperation and subsequent project implementation.

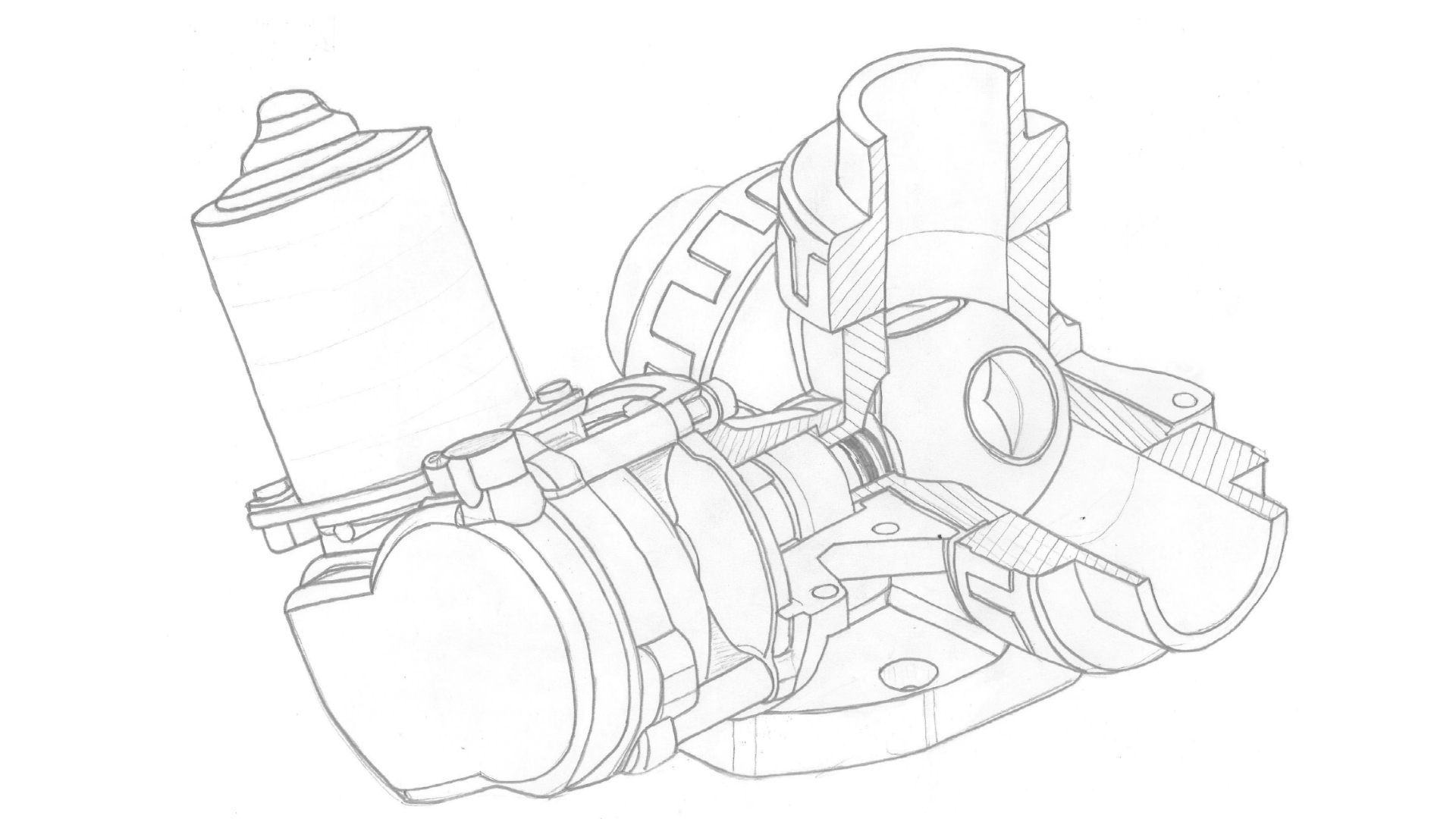

Conceptualization and design

Product concept | variant design | technology comparison | framework and boundary conditions

At the beginning of every new development, an optimal product concept is the cornerstone for a successful mechatronic product. To this end, the appropriate framework conditions such as markets, technology, environmental influences, costs, performance, installation space or design are determined and suitable parameters are defined.

With an initial concept, the necessary functions and technologies are defined and put together to form an optimum overall package. To ensure product success, technology comparisons and benchmarks of different concept variants prove their worth.

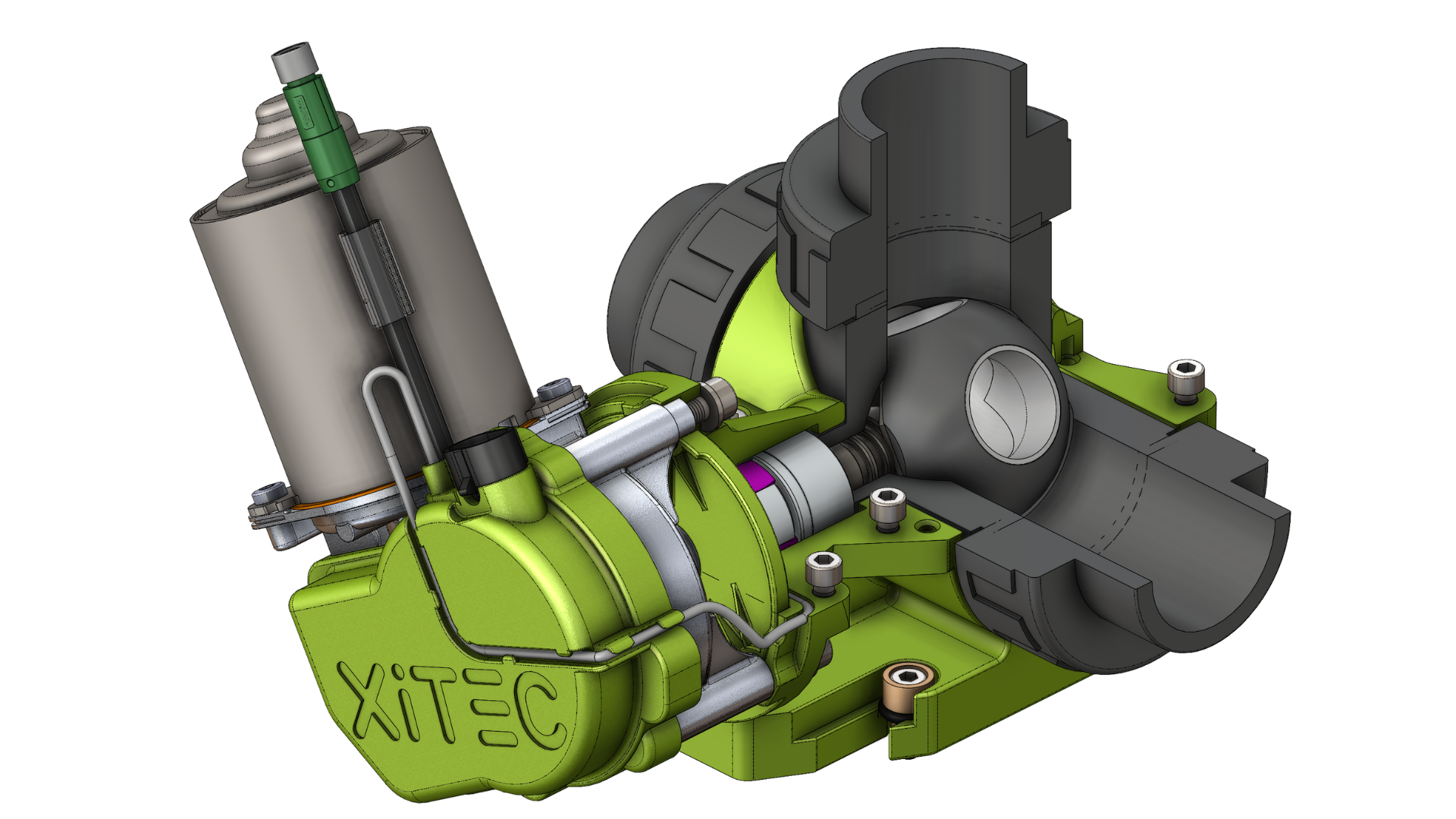

Design and development

Prototype design | Component design | Production-oriented detailed drawings | Component integration

Close coordination of electronics, mechanics and software is necessary in the development of mechatronic systems. Only a holistic approach to the problem and close coordination of the individual disciplines can ensure a successful product.

Regardless of the phase of product development, design using modern CAD systems is a central point. An optimum technical and economic solution can be achieved through innovative solutions and detailed designs that are suitable for production.

Whether the basic design of a BLDC motor, gearbox or spindle system, the technical design of the components and the functions to be achieved with them determine the properties of a component.

The interface characteristics of individual components and assemblies and the implementation of electronics and software are taken into account by our engineers throughout the entire development process. Interactions between the individual systems are thus coordinated at an early stage.

Calculation and simulation

Gearbox design | Mechanical calculation | Machine elements | Linear & non-linear FEM

Through the calculation and simulation of components or entire assemblies, our engineers gain an early overview of the technical characteristics of the development. This allows component parameters to be optimized before prototypes are built. Various scenarios can therefore be virtually mapped and virtually tested.

Industrialization

Quality assurance | component coordination | component sampling | Supplier interface

The transfer of development to series production is the

final step in the product creation process. With our experience in the series production of mechatronic components

we support our customers in assembly and production planning. But

Supporting the start of series production, supplier selection, quality planning and assurance, assembly instructions and technical documentation are also important steps towards the finished product.

Ongoing support

Customer Support | Contact | Exchange

As a full-service partner, ongoing support is simply part of our package.

Technical products are constantly evolving, which is why we support you in the ongoing development of your project.